Protect your workflow with fast stretch wrapper repair

Wiki Article

Understanding the Importance of Stretch Wrapper Repair Service for Ideal Packaging Effectiveness

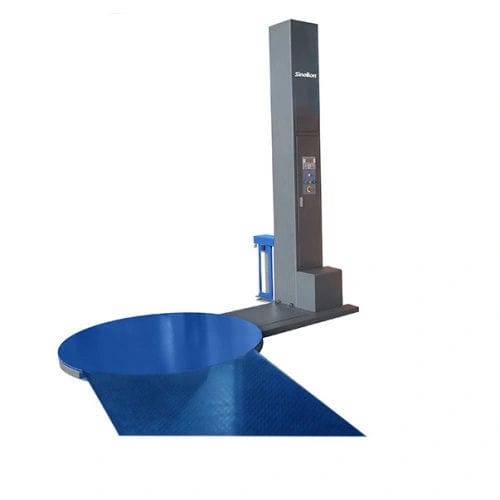

Stretch wrappers play a crucial role in ensuring packaging efficiency throughout various industries. Nonetheless, their efficiency can be compromised by usual issues that emerge over time. Overlooking fixings can result in substantial monetary effects and functional obstacles. Understanding the signs that suggest maintenance is needed is vital for maintaining performance. This raises the query of just how firms can successfully manage their stretch wrapper maintenance to preserve and protect against disturbances top quality.The Function of Stretch Wrappers in Packaging Effectiveness

Stretch wrappers act as vital elements in the product packaging process, considerably enhancing efficiency in various industries. These makers utilize stretch movie to safeguard items on pallets, lessening movement throughout transit and storage. By snugly wrapping things, stretch wrappers secure them from damages, wetness, and contamination, ensuring they reach their destination intact.In enhancement to protecting items, these wrappers simplify the product packaging process. Automated stretch covering systems considerably boost output, decreasing time and labor costs linked with hands-on product packaging. The regular application of tension in the wrapping procedure additionally maximizes product usage, bring about cost savings and lowered waste.Moreover, stretch wrappers can be adapted to suit different item shapes and sizes, providing convenience in product packaging operations. This adaptability enables firms to enhance their total performance, preserve high standards of quality assurance, and improve consumer complete satisfaction via dependable shipment of well-packaged items.Common Problems That Influence Stretch Wrapper Performance

Packaging effectiveness can be considerably impeded by different concerns that affect stretch wrapper performance. One typical problem is inconsistent tension during the covering process, which can bring about poor lots security (stretch wrapper repair). Additionally, malfunctioning sensors might fail to detect the load elevation, resulting in improper wrapping and wasted products. Tear and put on on elements such as rollers and belts can additionally disrupt the smooth operation of the machine, creating delays and potential damage to products. One more problem is the quality of the stretch movie itself; substandard products can tear easily or fail to adhere effectively to the lots. Regular maintenance is necessary to determine and correct these problems prior to they rise. Ultimately, ensuring peak performance of stretch wrappers not only enhances product packaging effectiveness yet additionally maintains product integrity throughout the supply chain. Addressing these usual issues is crucial for keeping effective packaging proceduresThe Financial Effect of Neglecting Stretch Wrapper Services

Overlooking stretch wrapper repair work can bring about considerable monetary consequences for companies. Raised product packaging expenses and prolonged downtime outcome in productivity loss, inevitably influencing the bottom line. Addressing these repair services promptly is necessary to maintain operational performance and cost-effectiveness.Increased Product Packaging Expenses

Over time, falling short to attend to required repairs on stretch wrappers can bring about considerable monetary consequences for organizations. As tools malfunctions or wears down, packaging effectiveness decreases, causing enhanced material usage. This can show up as the requirement for more stretch movie to protect loads properly, raising overall packaging costs. On top of that, poorly wrapped products might result in harm during transportation, demanding added expenses for replacements and customer compensation. Companies may likewise locate themselves investing in expedited delivery to change damaged products promptly, which even more strains their budget plans. Eventually, disregarding stretch wrapper repairs not just boosts immediate product packaging expenses however can also add to long-lasting monetary instability, impacting productivity and competition in the market.Downtime and Productivity Loss

Downtime positions a considerable threat to operational effectiveness in any kind of company counting on stretch wrappers. When these machines experience breakdowns, manufacturing stops, leading to substantial performance losses. Each hour of inactivity not just weakens workflow yet additionally boosts labor costs as employees stay still. In addition, delayed shipments can damage consumer partnerships and tarnish a firm's credibility. The financial effects are extensive; disregarding timely repair services can lead to cumulative losses that much go beyond the price of upkeep. By prioritizing stretch wrapper upkeep, companies can reduce downtime, enhance productivity, and guarantee constant functional flow. Inevitably, buying routine repairs safeguards success and sustains affordable advantage in a requiring market.Signs That Your Stretch Wrapper Needs Upkeep

Exactly how can one tell when a stretch wrapper calls for upkeep? Several indications indicate that a stretch wrapper might not be operating at peak effectiveness. First, inconsistent covering tension may bring about loose or overly tight loads, endangering bundle stability. Furthermore, if the device creates excessive noise or vibrations during procedure, it might symbolize worn elements that require interest. Operators ought to additionally observe the movie's application; if there are splits or creases, this can direct to issues with the movie carriage or the stress settings.Frequent mistake messages or alarm systems throughout procedure are another clear sign of potential troubles. Additionally, if the cycle time increases, it might suggest that the stretch wrapper is having a hard time to do at its best. Consistently looking for these indicators can aid assure that upkeep is set up before even more significant issues arise, ultimately contributing to the general performance of the packaging procedure.Advantages of Normal Stretch Wrapper Maintenance

Normal upkeep of stretch wrappers provides significant benefits for packaging operations. It not only extends the lifespan of the devices however likewise reduces downtime expenses and boosts the general top quality of product packaging. By prioritizing maintenance, business can improve performance and assurance consistent performance in their product packaging procedures.Boosted Tools Life-span

Keeping a stretch wrapper not only improves product packaging efficiency but also considerably prolongs the equipment's lifespan. Regular upkeep practices, such as cleaning, lubrication, and timely substitute of used parts, avoid premature deterioration, guaranteeing that the device operates at peak efficiency. By resolving small issues prior to they rise, operators can prevent considerable damages that can lead to pricey fixings or the requirement for a complete replacement. Additionally, constant upkeep fosters a much better understanding of the equipment's operational limits, permitting suitable use without overexertion. This positive strategy inevitably contributes to a much longer operational life for the stretch wrapper, making best use of the roi for organizations and making sure reliability in their product packaging procedures.

Minimized Downtime Expenses

Efficient operations depend upon lessening downtime, especially in high-demand packaging atmospheres. Routine maintenance of stretch wrappers notably you could try this out minimizes the chance of unexpected failures, which can lead to pricey manufacturing halts. By proactively attending to minor concerns prior to they escalate right into major failings, firms can assure that their product packaging lines stay functional. This preventative technique not only saves time however likewise decreases labor prices associated with emergency situation repair services and unplanned downtime. On top of that, consistent maintenance allows for far better scheduling of fixings, leading to much less disruption throughout peak operational hours. Because of this, the overall productivity of the product packaging procedure boosts, translating right into greater performance and expense financial savings for the organization. Routine stretch wrapper maintenance is vital for keeping operational consistency in affordable markets.Enhanced Packaging Quality

When stretch wrappers are correctly preserved, the top quality of product packaging can considerably enhance, guaranteeing that items are safely wrapped and shielded throughout transportation and storage. Regular upkeep helps in determining and correcting prospective concerns prior to they rise, such as imbalance or endure components, which can endanger the wrapping procedure. This aggressive strategy not only improves the stability of the wrapped items however additionally reduces the threat of damage brought on by environmental aspects. In addition, consistently properly maintained stretch wrappers contribute to uniformity in product packaging, making sure that each tons satisfies the required standards. Inevitably, enhanced product packaging top quality causes enhanced customer contentment, decreased return rates, and a more powerful online reputation for reliability, all of which are vital for sustained organization success.Choosing the Right Repair Solution for Your Stretch Wrapper

Choosing the ideal repair solution for a stretch wrapper is important to preserving product packaging efficiency and minimizing downtime. Companies need to prioritize solutions that specialize in stretch wrapper fixings, as these service providers have the necessary experience and experience. Assessing the technician's certifications and the provider's reputation can substantially influence fixing quality.Additionally, it is useful to think about the schedule of substitute components and the rate of solution. A reputable repair service must not only provide punctual aid yet also offer guarantee choices for their work, guaranteeing long-lasting confidence in repairs.Furthermore, services need to look for testimonials and reviews from other clients to assess the service's performance and integrity. Clear communication relating to expenses and repair work timelines is additionally essential in establishing count on. Eventually, selecting the ideal fixing service can bring about enhanced functional efficiency, lowered prices, and improved performance for organizations counting on stretch wrappers for their packaging needs.Finest Practices for Stretch Wrapper Maintenance and Long Life

Routine upkeep is necessary for making sure the longevity and ideal performance of stretch wrappers. Constant inspections need to be carried out to identify wear and tear on elements, such as electric motors, rollers, and belts. Oiling moving components at recommended intervals reduces friction and extends tools life.Furthermore, drivers must be trained to utilize the machinery correctly, as inappropriate handling can result in early failures. Maintaining the work area clean and free of debris read here reduces the risk of mechanical damages and advertises a secure functioning environment.Replacing used or damaged parts immediately is vital; this protects against small issues from intensifying into pricey repair work. Additionally, keeping a log of maintenance tasks aids track the performance and solution background of the stretch wrapper.Frequently Asked Questions

Just How Usually Should Stretch Wrappers Be Serviced for Optimum Efficiency?

The frequency of servicing stretch wrappers generally depends on usage intensity. Typically, suppliers advise assessments every 6 to twelve month, guaranteeing peak performance and reducing unplanned downtime with proactive maintenance and prompt repair services.Can I Perform Repair Services on Stretch Wrappers Myself?

The specific contemplated whether they could execute repairs on stretch wrappers themselves. stretch wrapper repair. It was kept in mind that while some minor modifications might be manageable, professional expertise is often recommended for complex problems to guarantee safety and security and performanceWhat Parts of a Stretch Wrapper Are Most Prone to Failing?

Stretch wrappers frequently experience failures in elements such as the film carriage, drive motors, and sensors. These parts are integral to the equipment's procedure and may need normal maintenance or timely substitute to guarantee peak efficiency.

Exactly How Does Environmental Influence Impact Stretch Wrapper Performance?

Environmental factors, such as moisture and temperature fluctuations, can substantially influence stretch wrapper efficiency. These problems may cause material deterioration, inconsistent covering stress, and ultimately, reduced efficiency in the product packaging procedure. Routine assessments are necessary.Exist Particular Brands Known for Better Resilience in Stretch Wrappers?

Report this wiki page